21Dec

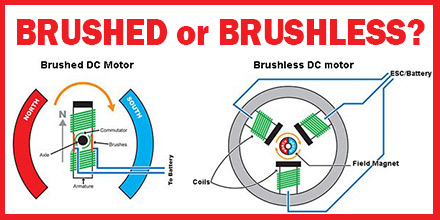

Brushed or Brushless Motor: What’s the Difference?

The biggest difference between brushed and brushless motors, unsurprisingly, is the brush. Otherwise, the principle behind the internal workings of brushed and brushless motors are much the same.

As the motor windings energize, it creates a temporary magnetic field to repel or attract permanent magnets. This magnetic force is converted to shaft rotation, allowing the motor to do work.

As the shaft rotates, the electric current is routed to different sets of windings. This maintains electromotive repulsion or attraction, forcing the rotor to continually rotate.

The biggest difference between brushed and brushless motors, unsurprisingly, is the brush. Otherwise, the principle behind the internal workings of brushed and brushless motors are much the same.

As the motor windings energize, it creates a temporary magnetic field to repel or attract permanent magnets. This magnetic force is converted to shaft rotation, allowing the motor to do work.

As the shaft rotates, the electric current is routed to different sets of windings. This maintains electromotive repulsion or attraction, forcing the rotor to continually rotate.

History of Brushed and Brushless Motors

The use of brushed DC motors began in 1856. Today, electrical propulsion, cranes, paper machines and steel rolling mills all use brushed motors. One problem with brushed motors is that the brushes wear down and require frequent replacement. Brush wear became a significant drawback as application demands increased and high-electric discharge noise became an issue. Hence, a new motor was born...the brushless DC motor. Brushless DC motors use electronic speed controller devices and quickly displaced brushed motors for many applications. Advancements in solid state technology in the early 1960s resulted in the invention of the first brushless DC (BLDC) motor in 1962. T.G. Wilson and P.H. Trickey called it a “DC machine with solid state commutation.” The key element of the brushless motor is that it requires no physical commutator, making it the most popular choice for computer disk drives, robotics, and aircrafts.Brushless Motor Advantages

Brushless DC motors, with no brushes to wear out, represent a huge leap forward in technology. They also provide significantly higher efficiency and performance. They also offer a lower susceptibility to mechanical wear than their brushed counterparts. Brushless motors offer several other advantages, including:- Higher torque to weight ratio

- Increased torque per watt of power input (increased efficiency)

- Increased reliability and lower maintenance requirements

- Reduced operational and mechanical noise

- Longer lifespan (no brush and commutator erosion)

- Elimination of ionizing sparks from the commutator (ESD)

- Near-elimination of electromagnetic interference (EMI)