With the threat of falling rocks and unsteady ground, mining inspection is a perilous task.

Until recently, inspection via robot faced many limitations given the obstacles to signal and sight.

But this may all be changing thanks to advancements in drone technology.

Drones go underground

Flyability, a Swiss manufacturer, designed Elios -- a collision-tolerant drone capable of conducting interior mining inspections.

Unmanned Aerial Services (UAS) teamed with Flyability to put Elios to the test. The challenge? Explore and inspect every nook and cranny of the North American Palladium Lac des Iles mine near Thunder Bay, Ontario, Canada.

The very construction of Elios is different to most drones. Surrounded by a protective frame, Elios is extremely tolerant of the inevitable collisions that occur in such an environment.

In fact, the design of Elios enables it to bounce off obstacles, readjust its path and continue the mission

Made of carbon fiber, this structure protects Elios against crashes and knocks up to 15km/h. This makes it perfect for operating in the close confines and varied environs of a mine.

The team quipped Elios to see into shadow zones which elude regular scans.

A call from a drone enthusiast

For Marc Gandillon, Marketing Manager at Flyability, and his team, Lac des Iles was the first opportunity to work in mining.

“One of the guys from the Lac des Iles mine contacted us saying he was using a Phantom 4 drone to explore some parts of the mine where he worked,” said Gandillon. “He was a drone enthusiast who had done some trials on his own already. He said, ‘I’m interested in a solution to one of the biggest problems with regular drones, that if you touch an obstacle then you crash and you break the drone.’”

Elios’s cage encloses and protects the entire drone -- propellers, cameras and lights included. Thus, crashing into an obstacle doesn't end the mission.

“The stability of the drones is extremely impaired in a mine, so you can’t just fly any kind of drone as it goes beyond line of sight, so you actually can’t see the drone, you can only see what the drone sees,” said Gandillon. “If you’re in a very narrow space there’s a high chance that you’ll hit something. You break a propeller and then your drone is left there because there’s no way to collect it. So the cage was necessary to explore that kind of environment.”

A dangerous industry, even for a robot

In operation for over 20 years, the Lac des Iles site is the only pure play palladium mine in the world. It includes both an open pit and an underground mine, with an estimated 2.78 million ounces of contained palladium.

As such, it is a complex mix of old and new galleries that must be managed properly to ensure that the mine is stable and secure.

The key benefit of using a drone in the mine is the improvement to safety.

“These kinds of environments are extremely dangerous,” said Gandillon. “The risk of accident is very high, because you may have rocks falling from the ceiling, or you can sometimes get vertical, 1000m deep galleries.”

Mining is a dangerous industry. In 2016, 63 deaths occurred in just the International Council on Mining and Metals-registered companies. One of the major causes was fall of ground.

Inspections are vital to the safety of the workers.

Elios can safely look for cracks and other indicators of instability without causing ground disruption. Any ground disruption could lead to rock fall and other potentially hazardous scenarios.

“It’s just impossible to involve a human in some spaces because there is no standing. You could put rope access but then you’re still threatened by some rocks that could fall on your head, so it’s a dangerous environment,” said Gandillon. “Robots are just logical.”

Elios and the mine

The UAS team took full advantage of Elio's technology -- sending it on several missions. There inspections brought back many results.

“First, we found the ground had moved in one of the galleries and this created an open cavity alongside the gallery,” said Gandillon. “They wanted to know the size of this space.”

Instead of using traditional scanners, which rarely give a picture of the entire space, the team dispatched Elios.

In addition, Elios mapped important indicators within the mine, such as dykes. This inspection was particularly used to check ceilings after they have been blown out.

Finally, Elios measured the expensive and time-consuming task of back-filling the spent galleries.

“They did a scan and there were some shadow areas,” said Gandillon. “They wanted to know how much back-filling was needed so they wanted to know the size of this shadow area. As well as the sealing of the open cavity, on top of that cavity you have an open gallery and you need to know when you roll over it in a truck, it won’t fall through the ground.”

As such, the confidence a drone scan can provide with regards to back-filling is very attractive.

Sensitive signal propagation

The Flyability team overcame several challenges inherent to working in a mine.

“The main problem that is quite sensitive is the signal propagation. To control the drone you need to have a radio signal connection between the drone and the remote controller,” said Gandillon. “The environment constantly absorbs the signals energy. So, if you go too far away then you lose signal and you can’t bring the drone back.”

Flyability turned to partner DJI to solve this particular challenge, integrating the Lightbridge 2 transmission system into the drone. This is efficient enough to allow Elios to fly 150m away, down curved, underground passages and tunnels without any loss of signal coverage. It also sends a constant video stream of what the drone can see.

For mining applications, the potential of drones is just in the beginning stages. With Elios’s ability to fly without fear of the knocks and bumps inevitable in such an inhospitable environment, the technology continues to prove adaptable enough to meet the industry’s needs.

With the threat of falling rocks and unsteady ground, mining inspection is a perilous task.

Until recently, inspection via robot faced many limitations given the obstacles to signal and sight.

But this may all be changing thanks to advancements in drone technology.

With the threat of falling rocks and unsteady ground, mining inspection is a perilous task.

Until recently, inspection via robot faced many limitations given the obstacles to signal and sight.

But this may all be changing thanks to advancements in drone technology.

An Ingress Protection Rating, or IP rating, is a laboratory-certified industrial rating for a piece of electronic equipment or an enclosure for electrical equipment.

The IP Rating explains the degree of protection provided against debris and water intrusion. It also measures protection against accidental contact -- including body parts like fingers or hands -- to critical components.

Developed by the International Electrotechnical Commission (IEC), this internationally recognized rating system is in wide use in Europe and Asia. North America is adopting this standard at a slower pace.

An Ingress Protection Rating, or IP rating, is a laboratory-certified industrial rating for a piece of electronic equipment or an enclosure for electrical equipment.

The IP Rating explains the degree of protection provided against debris and water intrusion. It also measures protection against accidental contact -- including body parts like fingers or hands -- to critical components.

Developed by the International Electrotechnical Commission (IEC), this internationally recognized rating system is in wide use in Europe and Asia. North America is adopting this standard at a slower pace.

SPH Engineering announces the launch of UgCS centralized drone management solution for Police, Search and Rescue, Firefighter and Security Service Command centers for efficient drone implementation in first response and surveillance operations.

This centralized solution was presented at MiliPol 2017.

SPH Engineering announces the launch of UgCS centralized drone management solution for Police, Search and Rescue, Firefighter and Security Service Command centers for efficient drone implementation in first response and surveillance operations.

This centralized solution was presented at MiliPol 2017.

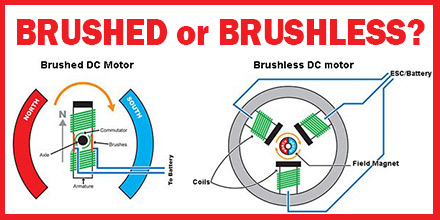

The biggest difference between brushed and brushless motors, unsurprisingly, is the brush. Otherwise, the principle behind the internal workings of brushed and brushless motors are much the same.

As the motor windings energize, it creates a temporary magnetic field to repel or attract permanent magnets. This magnetic force is converted to shaft rotation, allowing the motor to do work.

As the shaft rotates, the electric current is routed to different sets of windings. This maintains electromotive repulsion or attraction, forcing the rotor to continually rotate.

The biggest difference between brushed and brushless motors, unsurprisingly, is the brush. Otherwise, the principle behind the internal workings of brushed and brushless motors are much the same.

As the motor windings energize, it creates a temporary magnetic field to repel or attract permanent magnets. This magnetic force is converted to shaft rotation, allowing the motor to do work.

As the shaft rotates, the electric current is routed to different sets of windings. This maintains electromotive repulsion or attraction, forcing the rotor to continually rotate.

An unlikely contender in the battle for wildlife conservation has entered the ring: drones.

Thanks to an ability to cover large areas at low costs, drones are playing a part in the reduction of wildlife threats.

Globally, drones aid in everything from migration tracking and nest surveys to habitat management and anti-poaching activities.

Drones are changing wildlife conservation around the world.

An unlikely contender in the battle for wildlife conservation has entered the ring: drones.

Thanks to an ability to cover large areas at low costs, drones are playing a part in the reduction of wildlife threats.

Globally, drones aid in everything from migration tracking and nest surveys to habitat management and anti-poaching activities.

Drones are changing wildlife conservation around the world.

At the request of U.S. national security and law enforcement agencies, the

At the request of U.S. national security and law enforcement agencies, the